The LED lighting industry has evolved significantly over the last decade, offering more energy-efficient, versatile, and design-friendly lighting options. Among the most popular choices today are LED strip lights and LED modules, especially for businesses sourcing them at scale. Whether you’re lighting up commercial spaces, signage, or architectural features, the quality of your lighting products and who you get them from can make a noticeable difference.

This guide explores the key considerations when dealing with wholesale LED strip lights and how to evaluate a dependable LED module manufacturer.

Understanding LED Strip Lights for Larger Projects

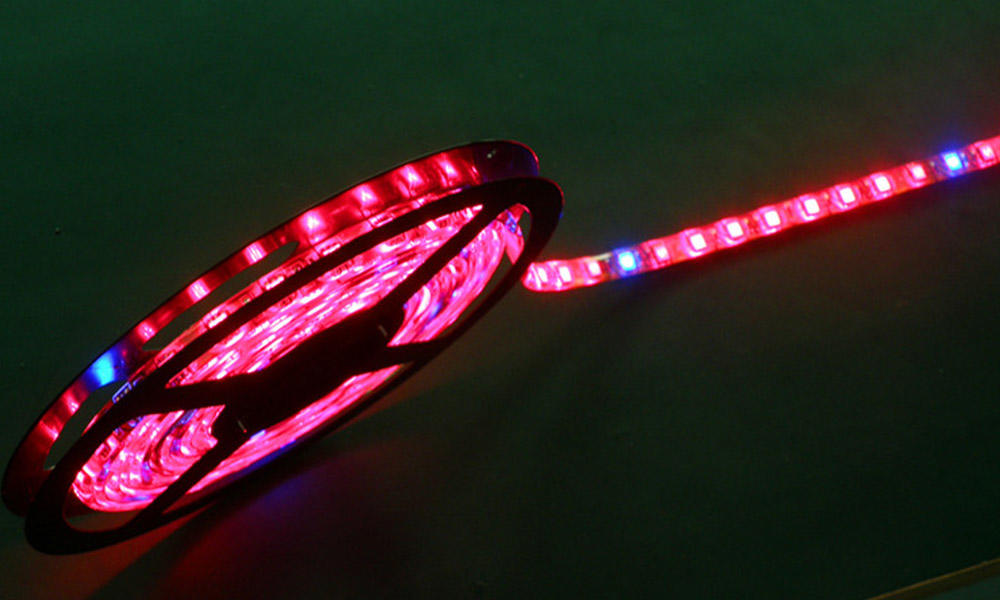

LED strip lights, also known as LED tape or ribbon lights, are long, flexible circuit boards populated with LED chips. They’re ideal for accent lighting, under-cabinet installations, signage backlighting, and decorative applications in both residential and commercial settings.

When looking into bulk options, understanding the basic configurations is helpful. LED strips are usually categorized by:

- Chip type (e.g., SMD 3528, 5050, COB)

- Voltage (commonly 12V or 24V)

- Water resistance (IP20 for dry areas to IP68 for fully waterproof use)

- Brightness (measured in lumens)

- Color rendering index (CRI), which affects how accurately colors appear under the lighting

Buying Considerations for Large Orders

Purchasing LED lighting in large quantities means you’ll want to think beyond just unit cost. Consistency across all units is key no one wants mismatched colors or brightness shifts once everything is installed.

This is where selecting wholesale LED strip lights becomes more than just a logistical decision. You need to assess quality across a batch: Is the brightness uniform? Is the adhesive backing reliable? Are the copper traces thick enough for good heat dissipation? These are the kinds of technical questions that can help avoid installation and longevity issues later.

It’s also helpful to confirm whether the strips are compliant with common standards like CE or RoHS, and whether they come with proper installation guides, especially for large-scale or complex projects.

Spotlight on LED Modules

Unlike strip lights, LED modules are generally used in signage, channel letters, and backlighting applications. These are self-contained units that are wired and often waterproofed, making them ideal for outdoor use or confined spaces that require directional lighting.

Applications vary widely some modules are used for backlit logos, others for retail displays or architectural highlights. What they all share is the need for consistent performance in often unpredictable environments.

In this context, finding the right LED module manufacturer becomes a critical part of planning. You’re not just ordering a product; you’re relying on the supplier’s engineering, materials, and quality control to maintain your own standards.

How to Evaluate the Right Manufacturer

Working with a trusted manufacturer means looking past the product page. It’s worth examining:

- The chips they use (Epistar, Osram, and Samsung chips usually indicate strong reliability)

- How well the modules are sealed (injection-molded housings offer better waterproofing)

- How the heat is managed (better heat dissipation = longer module life)

- Voltage stability (important for avoiding flicker or early failure)

You can also ask for technical documentation or a small sample run before placing a large order. That allows you to test performance under real conditions and avoid surprises during installation.

New Trends in LED Design

Technology in LED lighting keeps moving forward. Today’s strips and modules often include flexible form factors, higher CRI scores, and energy efficiencies that would have been hard to imagine a few years ago. Some products now boast operational lifespans of 50,000 hours or more, reducing the long-term costs of maintenance and replacements.

Eco-conscious design is also gaining momentum. Suppliers offering recyclable packaging, reduced-wattage modules, and efficient logistics are now aligning with sustainability goals without sacrificing performance.

Summary: What to Keep in Mind

Choosing the right products and the right suppliers is a process that requires more than checking boxes on a spec sheet. Think about long-term use, not just the initial purchase. Will these components stand up to your working conditions? Will your lighting look as good six months from now as it does today?

When evaluating options for LED strip lights and modules, your decisions will impact quality, cost-efficiency, and project outcomes.

Final Thoughts

If you’re in the early stages of planning or procurement, now’s a good time to map out your technical needs, request sample units, and compare product details carefully. With a little upfront research, you can set yourself up for a smooth and reliable lighting installation whether you’re handling signage, architecture, or ambient design.