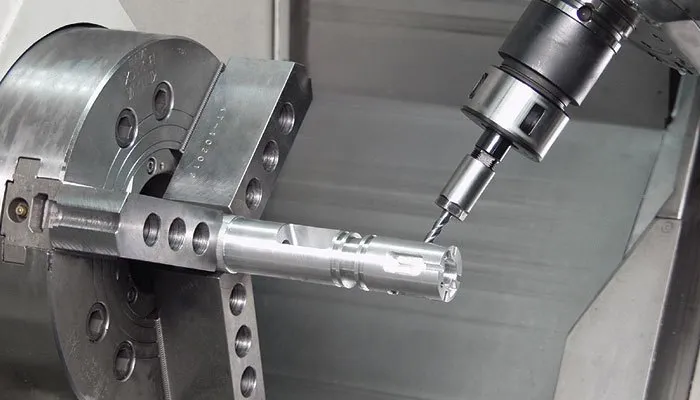

CNC machine services are acquiring popularity nowadays. CNC stands for Computer Numerical Control, a computer-based system that manages the motion of machines like lathes and milling machines. In other words, it regulates how well the machine tool can perform cutting or grinding tasks.

It may also refer to a device that uses a computer or network of computers to autonomously regulate the movements of industrial operations (e.g., robot systems). Furthermore, it is a computer-controlled machine that is used to cut, route, and carve materials including wood, plastic, and metal to produce three-dimensional items.

Since they can swiftly and precisely produce both tiny and large quantities of components, CNC machine services are often used in the industrial sector. This guide will provide you with everything you should know about CNC machines.

Types Of CNC Machines

Hardwood, rubber, metal, plastic, and stone may all be cut, shaped, and engraved using CNC machines, which are automated computer-controlled machinery. The capabilities of several different kinds of CNC machines vary. The type of material they operate with and the equipment size may be used to categorise them. These includes:

- Lathe machine. This is used to shape wood, plastic, and metal materials by rotating them around an axis.

- Laser cutter machine. This device uses lasers to cut materials rather than cutting tools.

- Router machine. This device cuts materials like wood or plastic by rotating a cutter head that is fitted with numerous bits to produce varied shapes and patterns.

- Milling machine. This tool can cut metal, plastic, and wood.

How Important Is CNC Machining?

Complex forms may be produced by machines using the technique of CNC machining. It is a popular method of making high-quality components since it is both economical and efficient.

The industrial industry now needs more qualified people due to the adoption of CNC machine services such as forged custom metal fabrication. More competent employees are required to run machines as more are produced. Companies are now investigating AI technologies that may assist in automating and enhancing the manufacturing process in order to close this gap.

Advantages of CNC Machines

Industries are using CNC machining to remain competitive as a result of the rising market for high-quality goods.

There are several advantages to CNC machine services. These include the capacity to make components with high precision and accuracy while economising on time and resources. Additionally, it enables high-speed machining, which helps reduce material waste. It is capable of producing intricate forms, such as components with cavities or threads. Because it consumes less energy than conventional techniques like hand machining or milling machines, the procedure is also ecologically benign. The following are some benefits of CNC machines:

Greater Speed

Because CNC machines don’t need to pause for tool changes or loading/unloading procedures as traditional machining techniques do, they can operate at more incredible speeds than conventional machining methods do.

Has Automatic Tool Changers

These devices replace the tools as they become worn out or dull. When changing tools manually, this reduces time and cost.

Accurate

CNC machines are just as accurate as traditional machining techniques. This is due to the machines’ use of sensor feedback to continuously ensure that the tool path and cutting forces are precise. Thus, there is reduced wastage and error.

Don’t Need Highly Experienced Operators.

CNC machines may be programmed to perform a particular operation without human interaction.

Shorter Lead Times

CNC machines can create parts faster than conventional machining methods because they need less setup time and production procedures.

Disadvantages of CNC Machine

CNC machines have shown to be quite beneficial for the manufacturing sector. They have aided in raising both productivity and product quality. However, they also have certain drawbacks, among them are:

Lack of Adaptability

CNC machines aren’t adaptable enough to make various goods with various requirements.

High-Cost

Compared to other machining manufacturing processes like stamping, casting, and injection moulding, CNC machines that can manufacture vast numbers of items are expensive to purchase. They also have high product unit costs.

Restricted Production To Materials

The producer cannot utilise a CNC machine to produce other materials, such as leather or wood, which may be used as low-cost substitutes in other sectors.

Conclusion

Due to their effectiveness and precision, CNC machines are growing in popularity in the industry. They are used in a variety of industrial processes, including production, engineering, prototyping, and others.

There are many different pricing points for CNC machines. However, its features and brand reputation heavily influence a CNC machine’s pricing. Furthermore, how much time you wish to spend using a CNC machine will determine its cost. If you want to use it for personal purposes, you’ll need to pay no more than €1,000; however, if you want to use it professionally, the price will be higher.

Due to the growing market for expensive products, industries are utilising CNC machining to stay competitive. Find CNC machine services near you.