Production and Quality Assurance

Quality assurance is among the most significant regions of the manufacturing process. This is often actually the part which will come inside the very finish within the production in which the final item is checked for defects and errors before selling it for the customers. Helpful to the people who because not just it cuts lower over the errors being created, but furthermore prevents humans from products which may be potentially hazardous.

For virtually every large area of the industrial history, inspection job was conducted by humans, nonetheless the businesses could use advanced technological systems to enhance their qc. Industries which take part in producing finish products like gadgets, pharmaceuticals, consumer goods, beverages and foods etc can hugely take full advantage of visual inspection systems simply because they offer mortgage loan business cost and greater precision and reliability together with excellent mechanical stability.

Just How Can Visual Inspection Systems Work?

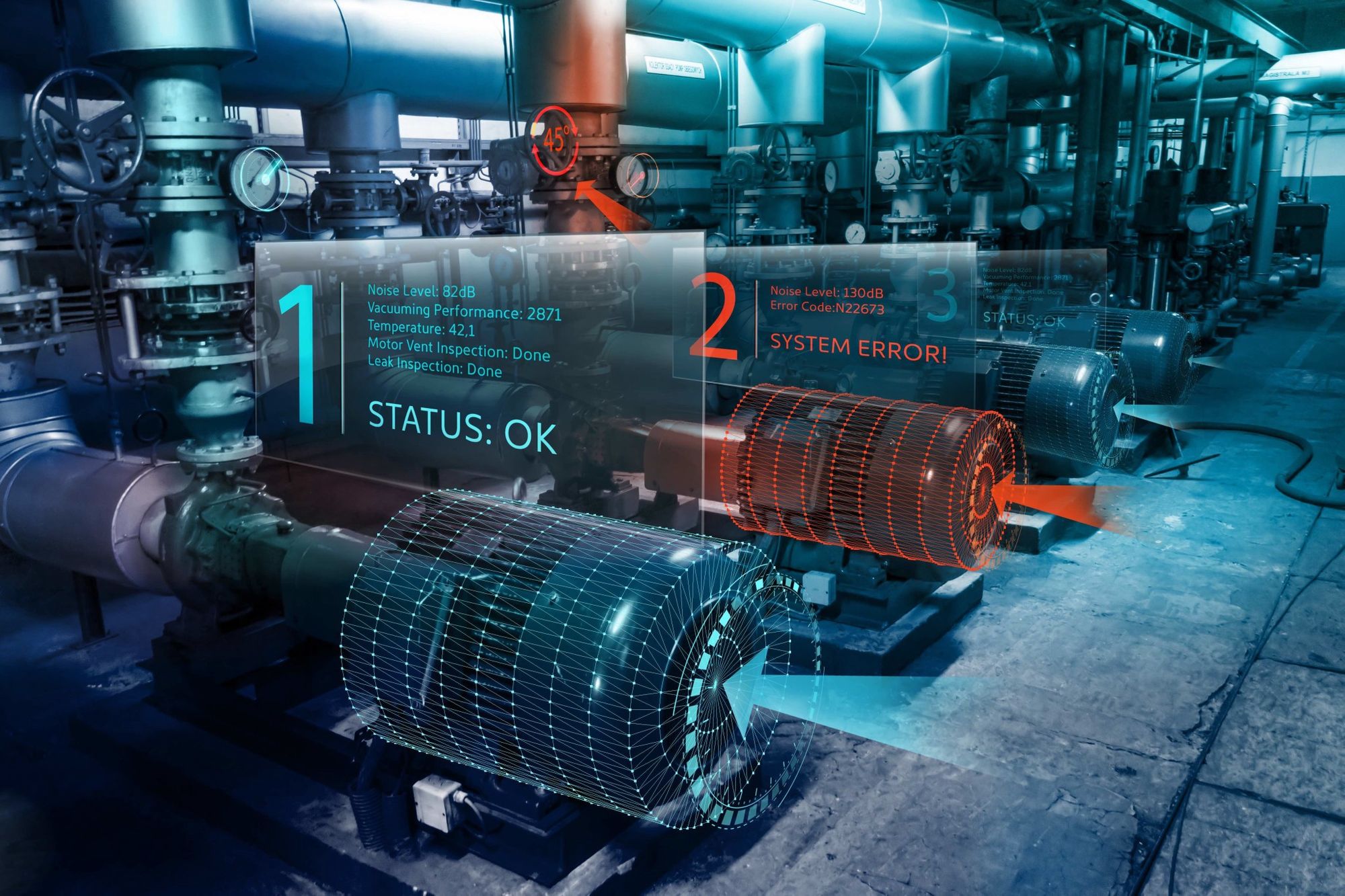

Visual Inspection Systems take use of digital sensors that are protected within the cameras. These cameras make use of the optical sensors to think about images that are then processed by computers to be able to measure specific characteristics for selection. They enjoy the needs of artificial intelligence to produce accurate and faster comparisons regarding the correct stereotypes and real products.

Regions of Visual Inspection Systems:

Lights: Lights assist in creating a feature standout so it might be taken clearly within the cameras.

Lenses: Lenses present the pictures for the sensors, that are really machine vision cameras and so are created to alter light into images within the digital form.

Vision Process: They focus on certain algorithms which appraise the images and extract all of the possible more understanding about defects and errors observed within the image.

Advantages of Visual Inspection Systems

After visual inspection systems are actually programmed and tuned for the manufacturing process, they may perform substantial quantity of production checking within the really short period of time when compared with human inspection.

In human inspection systems, generally there’s a considerable possibility of errors plus it does not matter how experienced and focused the workers are, these errors will not be introduced right lower getting a small level. Human abilities have limitations which visual inspection systems haven’t. And that’s why they take away the options of error in inspection obtaining a diploma and offer a bigger quality of products.

An additional advantage of visual inspections is simply in situation production method changes, scalping systems also adjust accordingly with great ease.

Furthermore they boost the production efficiency. They may catch errors inside the faster rate. Analysis of people observed defects might be produced quickly and necessary corrections might be produced immediately.

Unlike humans, scalping systems perform nonstop for 25 five-four hrs with unparalleled diligence. They may also be operated and programmed within the faraway place.

Primary Point Here -Conclusion

This is often really to conclude. Utilizing a visible inspection system within the production process, companies can increase production in addition to assist apparent within the wastage that’s generated by defected and faulty products. This might save not just their revenues, but furthermore ensure complete customer support.